-

RETAIL LABELLING & BARCODING

RETAIL LABELLING & BARCODINGEasily identify product information with the right Labelling Solution.

Concentrate to the change in retail:

What the right solutions are best for you to enable you keep effective?

Learn Detail > -

MANUFACTURING LABELLING & BARCODING

MANUFACTURING LABELLING & BARCODINGKeep track of raw materials and finished goods throughout the Production Process.

Focus on the change manufacturing:

What the right solutions can assist you keep effective?

Learn Detail > -

FROZEN FOOD LABELLING & BARCODING

FROZEN FOOD LABELLING & BARCODINGEasily identify product information with the right Labelling Solution.

Freezer-grade labels are made with polypropylene film and an adhesive that will stay strong during freezing conditions. Typical label adhesive isn't designed for cold temperatures and can crack and peel when exposed to freezing temperatures.

Learn Detail > -

ASSET LABELLING & BARCODING

ASSET LABELLING & BARCODINGKeep track on important assets with the right Labelling Solution.

Our asset identification labels, tags and plates are available in a wide range of materials, sizes and designs, with a permanent adhesive making them extremely difficult to remove. This means you can find the perfect asset marking solution for your business or organisation.

Learn Detail > -

LOGISTICS LABELLING & BARCODING

LOGISTICS LABELLING & BARCODINGMaintain item visibility with the right Labelling Solution.

Our solutions integrate seamlessly into your existing workflows and networks and will help to reduce costs, manage demanding timings, whilst improving overall business efficiency in today’s increasingly challenging Transport & Logistics operations.

Learn Detail > -

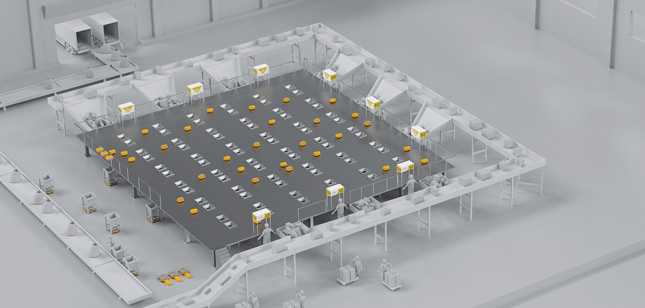

Steel platform sorting solutions

Steel platform sorting solutionsIntelligent sorting, precise, efficient, and highly cost-effective

Application Scenarios:

It can be applied to large sorting or picking centers in express, supermarket, clothing, e-commerce and other industries, suitable for parcel and express sorting, commodity sorting and other scenarios.

Learn Detail > -

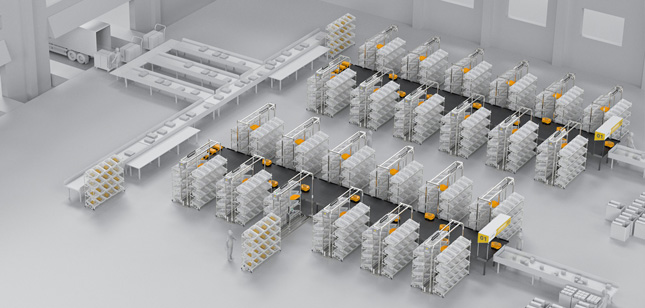

3D sorting solutions

3D sorting solutions3D vertical sorter easy process for large sortation volume

Application Scenarios:

Large wave order sorting for scenarios such as shoes & garments, e-commerce, and sales return, etc.

Learn Detail > -

T-sort sorting solutions

Flexible sorting solutions, no worries about space limitation

Application Scenarios:

Garments, retail, express delivery, fresh food (cold storage), jewelry, books and other industries involving warehouse sorting or picking centers. Suitable for order picking, parcel sorting, and other related scenarios.

Learn Detail >

Tel:+27 69 4121636

E-mail:blackrhino@blackrhinoai.com

Recruit:blackrhino@blackrhinoai.com

Location:Unit 1, 106 Loper Ave. Spartan, Kampton Park,1619