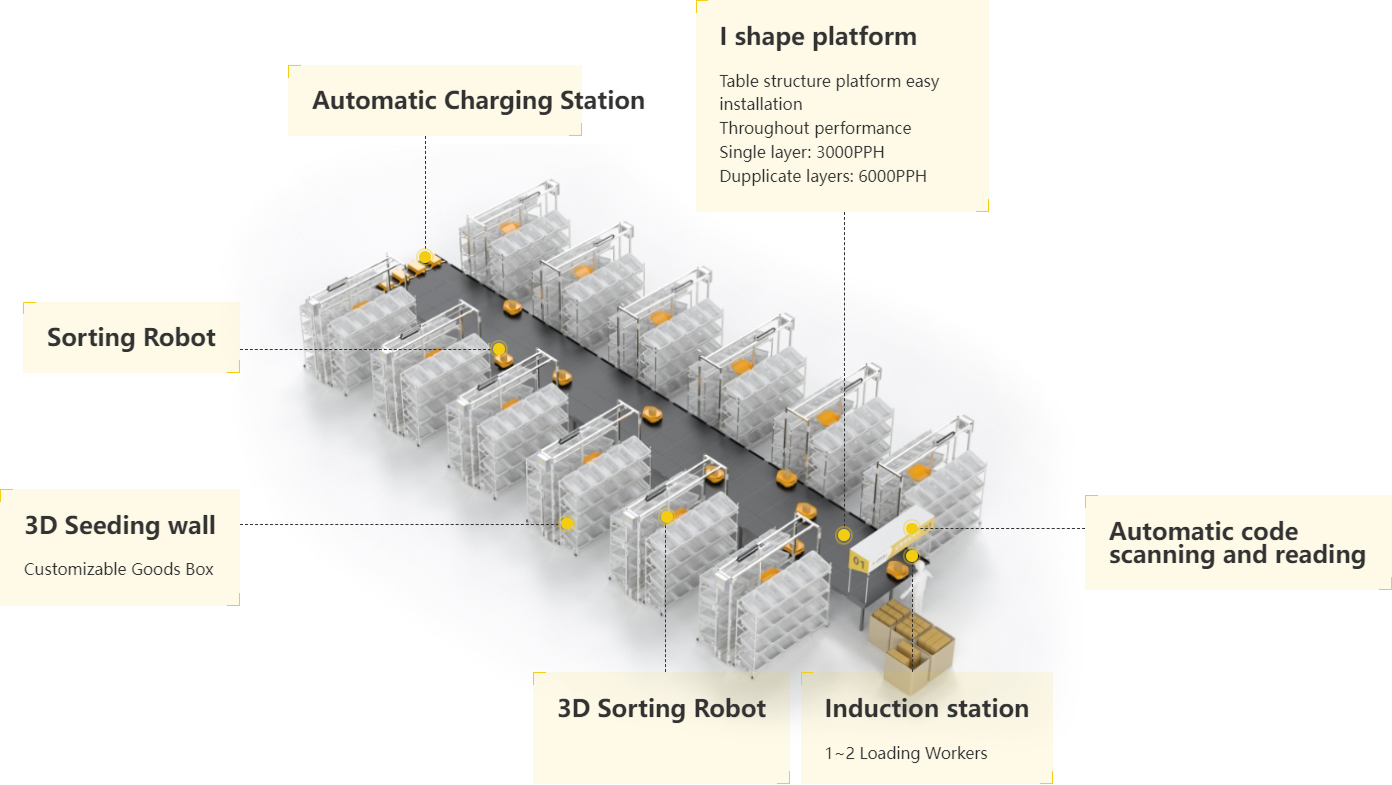

Solution Analysis

It consists of several parts, including the table platform (fixed system), 3D sorting robot (fixed system), robot sorting system (core system), and conveying system. The system is highly flexible and can increase or decrease robots as needed, allowing the layout of more sorting chutes, which can cope with very high traffic sorting demands.

Solution Strengths

Modular Design with More Flexible

·The system adopts a modular design with flexible expandability, which can be deployed in a quick and staged manner.

·The system is highly flexible, allowing the removal and fitting of components. Robots can be assembled, increased or decreased based on demands (in off-season or peak season).

High Stability and High Accuracy

·A single robot failure will not affect the overall system operations due to the high stability and fault-tolerance capabilities.

·Accuracy≥99.99%

High Stability and High Accuracy

·The unlimited increase of chutes perfectly meets the changing sorting needs, 20 to 10000.

·The size, quantity and material of the chute can be customized.

Space Saving and Convenient Deployment

·The construction period is 4-8 weeks, or minimum 1weeks

·Small Space Occupation

·Quick training, taking only 5 minutes

Flexible Dispatch, Intelligent & Efficient

·It effectively improves sorting efficiency, reduce manpower, saving 50-83% of general sorting labor, and over 50% of sorting labor

·The system can sort more than 600-1000 items at once

Cost reduction and efficiency increase

Flexible Investment, Short Return Period

·High investment flexibility

·ROI: 1~2 years